OLED technology, or organic light-emitting diodes, is used in a wide array of screen adaptations. From smartphones to wearable tech, we can find its involvement. The ability of small OLED displays to smoothly integrate into our daily lives is the reason it has become so widely accepted and sought after by all kinds of international developers and manufacturers.

The luminosity of different OLED materials creates an excellent foundation for building bespoke products. Coping with the thinness of screen size and the durability of the final product, you have a superior technology that can be introduced into practically any industry.

The Requirements of Luminescent Materials

Different materials make small OLED displays stand out and perform their function. Each material serves a specific purpose that you can find out in the following paragraphs.

Fluorescence characteristics with a high quantum efficiency: The luminosity has increased alongside the capabilities of green, orange, red, and blue OLED emitters, bringing an excellent viewing experience.

To reach a better effect, the luminescent material needs to have a high quantum efficiency. Its luminescent light should fall in the area of 400nm~700nm in fluorescence spectroscopy.

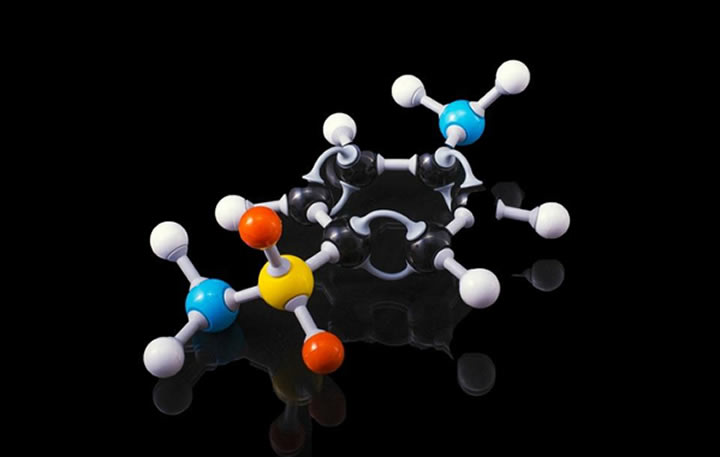

Semiconductor characteristics: The semiconductor characteristics relate to the high conductivity or ability to transfer electron holes of the carbon-based organic material sandwiched between two electrical contacts.

This material emits colored light without filtering out the white light, making it appear more vibrant, rich, and detailed, endowing the display with an excellent viewing angle.

Good film formation: Good film formation is achieved through using a new technology known as thin-film transistors (TFT), which grants higher resolutions displays with no pinholes at more economical production levels.

This is currently one of the driving factors behind Samsung, LG, and others as they use this tech to make cheaper and larger TV screens.

Good thermal stability: The high-temperature stability of the luminescent material is needed to ensure it can maintain the chemical properties during manufacture. This way, luminosity isn’t sacrificed no matter the size, power, or performance of small OLED displays.

The only downside is finding suppliers of the materials.

The Luminescent Materials that Satisfy the Requirements

Small OLED displays are made of luminescent materials that can handle the temperatures and pressure formations during each manufacturing stage. The two types of luminescent materials are:

High molecular polymer: High Molecular Polymer (molecular weight 10,000 ~ 100,000) uses a spin coating during film formation, making it incredibly easy to produce at a low manufacturing cost.

This is a good solution for some products whose durability and brightness are not that necessary. However, it can be difficult to purify when using this polymer, and the performance tends to suffer a bit in brightness and color.

Small-molecule organic compounds: Using small-molecule organic compounds (molecular weight 500 ~ 2,000) creates a more durable product. The method of vacuum evaporation film formation results in strong chemical modification.

There are multiple types of small-molecule organic compounds; therefore, you can select one from them for the characteristic of your products. It is easy to purify with a high quantum efficiency for luminance.

However, there is no denying that this material has concentration quenching as a disadvantage.

FET 2.23” OLED Display: Your Best Choice

Getting a quality small OLED display into your home appliances doesn’t have to be a challenge. FET, an industry-leading optoelectronics manufacturer, has many solutions, including a 2.23” 24 pins yellow OLED display that can be easily adapted into everything from toothbrushes to small appliance screens.

This device uses a passive matrix (PM OLED) with excellent quick response time to the input of your small appliance.

It only has a 2.027mm thickness which allows it to be easily integrated into smaller appliances that need space for motors or other elements that take up more room, all without sacrificing any of the 160 degrees viewing angle.

With a wide range of operating temperatures from -40 to 70 degrees Celsius, you don’t have to worry about including this small OLED display in hot or cold-related appliances often found in kitchens, breakrooms, and offices.

Where to Get Started

To learn more about where to buy OLED displays for your next project, visit the experts at FET (For future Electron Technology Co.). It is a professional manufacturer with a talented R&D team that produces some of the best quality small OLED displays available on the market.

They have the capability to get your orders completed at a competitive price with a high dedication to quality assurance. This results in an excellent product you can rely upon for your next project. So, visit FET’s website to get started!