3D printing was invented back in the 1980s, a fact that is quite astonishing, given how enhanced the technology is today. However, if you think about it, most of the modern 3D printer technology we are so used to now was originally invented decades ago, but only perfected over the years to reach the stage of evolution that we see today.

The large 3D printer is no exception either because modern 3D printers have evolved to reach a whole new level altogether. Let’s now take a look at some of the coolest and important applications of the 3D printer in 2019.

Prosthetics

The contribution of the 3D printers in the manufacturing of prosthetics for disabled individuals has been nothing short of revolutionary.

Use of the 3D printer technology in the field of prosthetics has made it more affordable and accurate, as the dimensions are created with exact precision for the patient a limb is supposed to fit. Through 3D printers, prosthetic limbs are now easier to manufacture as well, which means that there is never a shortage of supply with respect to demand.

Bones

Yes, it is now possible to replace human bones with 3D printed bones. In a way, it is similar to how prosthetics work, but infinitely more complex, as the bones go inside the body.

In China, the first vertebral implant was carried out successfully on 12-year old Minghao in Beijing, quite a few years back. Constructed from titanium powder using 3D printers, it was a better fit and safer replacement for the six original, cancerous vertebrae than any alternative methods could have ever been.

Although such 3D printing projects are not yet common in Canada at least, it is expected that the technology is there to do it, if required, which is quite amazing.

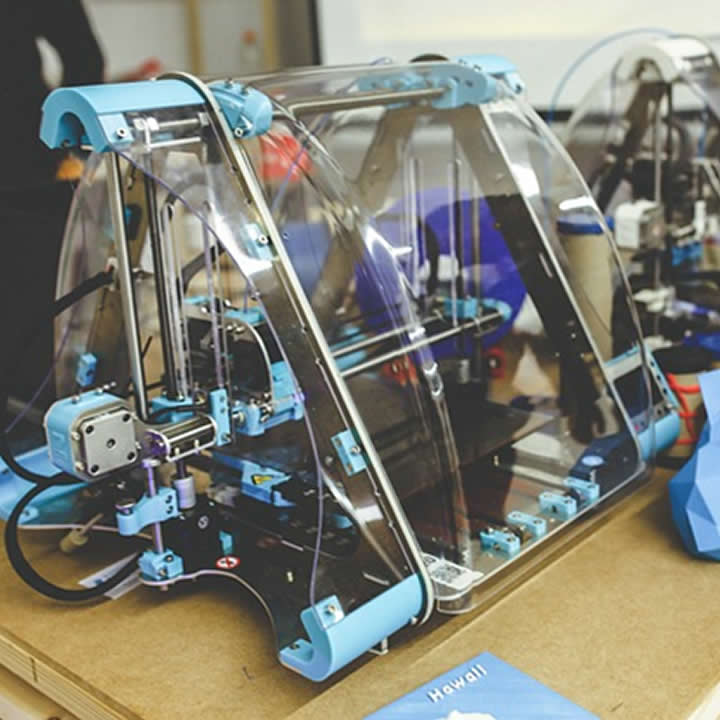

Industrial 3D Printing

Let’s take a look at the original reason for which the 3D printer was initially discovered because even today, it remains the primary use of 3D printers. Of course, 3D printers are still used to create prototypes, but 3D printing is now massive both literally and figuratively in the process of manufacturing.

Potentially massive parts like helicopter blades, the hull of a large yacht, parts of a submarine’s hull, construction machinery parts or even entire houses can be 3D printed these days by a large 3d printer of the industrial variety. The speed, efficiency, and accuracy with which these parts are manufactured on an industrial scale have made the manufacturing application of 3D printers irreplaceable.

Tissue Regeneration

We are still in the early stages of using 3D printers for bioprinting, of course, but one of Canada’s own research labs has invented a handheld 3D printer that can produce narrow sheets of skin tissue for treating burn victims in particular. Hearts and other vital organs are not that far away from being produced either at this point, which would save a lot of lives in the future.

A 3D printer is quite literally an invention which bridges the gap between the digital world and the real world. To think that we can have one of these 3D printing machines sitting in our own homes is an incredible testament to how far we have come in terms of technological evolution.