Laser engraving and cutting of rubber is a modern technology.

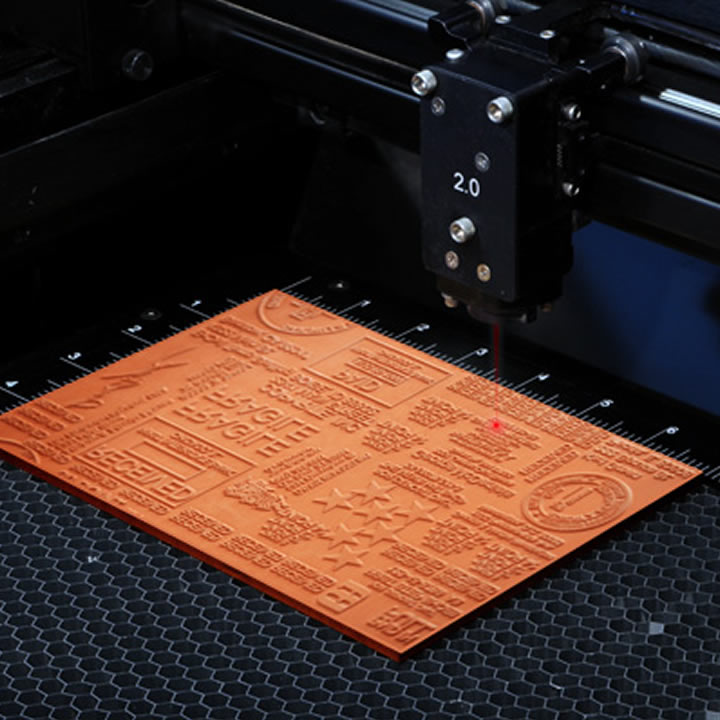

This technology involves using a laser beam to create precise cuts and designs on rubber materials. This technique is popular in various industries, including the manufacturing of rubber stamps, seals, gaskets, and other custom rubber products on Thunder Laser.

Laser cutting and engraving of rubber is a versatile process.

Laser cutting allows for the creation of intricate designs and shapes with high precision and accuracy. The laser beam melts or vaporizes the material along the cutting path, resulting in a smooth and clean cut without any fraying or rough edges.

Laser engraving on rubber can be used to create permanent markings or designs on the surface of the material. This technique is often used to add logos, text, or other decorative elements to rubber products.

Overall, laser engraving and cutting of rubber offer a precise, efficient, and customizable solution for creating high-quality rubber products. It is recommended to consult with a professional laser cutting and engraving service to ensure the best results.

Laser Cutting Rubber

Yes, it is possible to laser engrave and cut rubber.

Laser cutting and engraving is a very advanced technology that can be used on a variety of materials, including rubber.

When laser cutting rubber, a high-powered laser beam is used to vaporize and melt the material along the cutting path. This produces a precise and clean cut, without any of the rough edges or fraying that can occur with traditional cutting methods.

The result is a high-quality cut that requires minimal post-processing.

When laser engraving rubber, the laser beam is used to remove material from the surface of the rubber, creating a permanent mark. This can be used to create intricate designs or text on the surface of the rubber to learn more visit us.

It is important to note that not all types of rubber are suitable for laser cutting and engraving.

Natural rubber and some types of synthetic rubber, such as neoprene, can be successfully laser-cut and engraved. However, some other types of rubber, such as silicone rubber, may not be suitable for laser cutting and engraving due to their composition and physical properties.

It is recommended to consult with a professional laser cutting and engraving service to ensure that the rubber material is suitable for the process, and to determine the optimal settings for the laser machine to achieve the desired results.

Scope

In 2023, the scope for laser engraving and cutting of rubber is expected to continue to grow as the demand for customized and high-quality rubber products increases in various industries.

One of the major applications of laser engraving and cutting of rubber is in the manufacturing of rubber stamps, seals, and gaskets, which are commonly used in the legal, financial, and healthcare sectors.

As more businesses and organizations require customized rubber products with specific designs and sizes, laser engraving and cutting technology is becoming increasingly important for meeting these demands.

Furthermore, laser engraving and cutting of rubber are also used in the automotive, aerospace, and electronics industries to create custom rubber parts and components with precise dimensions and tolerances.

This technology allows for the creation of intricate designs and shapes that would be difficult or impossible to achieve with traditional cutting methods.

With the increasing availability of advanced laser cutting and engraving equipment and software, as well as the growing expertise of professionals in the field, the scope for laser engraving and cutting of rubber is expected to expand even further in the coming years.

Overall, the outlook for laser engraving and cutting of rubber in 2023 and beyond is promising, as the technology continues to offer a cost-effective, efficient, and customizable solution for creating high-quality rubber products.

Conclusion

In conclusion, laser engraving and cutting of rubber is a versatile technology that has a wide range of applications in various industries.

It offers a precise and efficient way of creating customized rubber products with intricate designs and shapes that are difficult or impossible to achieve with traditional cutting methods.

As demand for high-quality, custom rubber products increases, the scope for laser engraving and cutting of rubber is expected to continue to grow in 2023 and beyond.

It is recommended to consult with a professional laser cutting and engraving service to ensure the best results and to determine the optimal settings for the laser machine for the specific rubber material being used.