The application of injection molds is very common in our daily life. Your plastic cups, toothbrushes, pocket combs usually are made by plastic injection mold. Injection molding can not only deal materials like plastic, but mental, glass. Through this molding way, manufacturers can make a mass-production line, which is lower cost for their production.

Reading this article, you can get complete information about injection molding.

What Is Injection Molding?

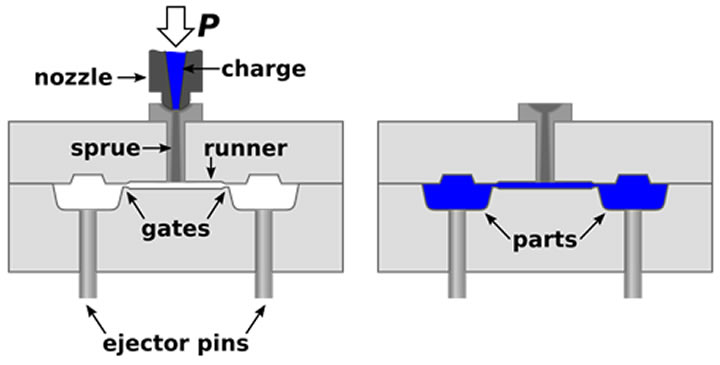

Injection molding is usually used in mass-production. Daily necessities, engine packaging, parts of machines or other special utilized things was made by injection molding. Injection mold machine usually has main parts as follow: nozzle, charge, runner, gates, ejection pins.

Molten material is injected from nozzle through charge to the runner. When it fully filled mold cavities, ejection pins push finished molds to leave from cavities.

How Does Injection Molding Work?

Injection molding deals with material not only plastic, but also glass, metal. Parts were made as we mentioned before. Molten material was injected from nozzle through charge to the runner. When it fully filled mold cavities, ejection pins push finished molds to leave from cavities. This is a complete process of mold making.

As a part of producing process, the injection mold machine can be designed as a part of production line. The more parts it produces, the little cost it will spend, which means injection molding is very suitable for mass-production, and that is why manufacturers buying injection expend their producing.

Not only for products manufacturing, little injection molds also can be used in other industries, just like food industry. Confection maker uses injection molds to produce candies.

What Is Injection molding Features?

Injection molding, with mass-produced functions, is preferred by manufacturers. But everything has its advantage and disadvantage, for injection molding, let us discuss what features it has.

Pros and Cons of Injection Molding

Pros:

Injection molding has low scrap rates. When we put molten material into the mold machine, it runs along the runner to mold cavities which is useful part made from. The funner is narrow and thin, thus the material it used is little. The waste that the injection molding create is little.

Injection mold can be used infinitely. When injection mold is made according to the requirements of products, it can produce a lot of products by a injection mold which will lower the cost of producing. For mass-production, injection molding is a good choice that manufacturers use a injection mold to produce a lot of products.

Cons:

Injection molding has huge up front cost. The cost of a injection molding machine producing is expensive. Generally speaking, you should find the production point which can break even the up front cost. The huge up front cost takes other problems, like difficult to make changes. Once a injection mold was made, it should be used in producing. Changing molds is another cost.

Injection molding requires long lead time. Before utilizing injection molds, you should melt material by high temperature, and lead them into the nozzle, which will spend a long time.

Injection molding usually has size limitations. It can not produce a large part by one-time. Injection mold can not control a large prat well, thus we usually make a limitation for a injection mold. Larger parts should be assembled through other process.

What We Should Consider When We Make Injection Molding?

As we talked before, the most problem we should consider when we make injection molding is cost. As we all known, injection molding is very repeatable, one injection mold can be used infinitely, while the up front cost is expensive which makes people reduce their mistake on injection molds making as much as possible.

Therefore, finding the point which can break even the profit and cost of production is necessary for every injection molding user. You should consider the entry cost, which are usually used to choose which injection mold is suitable for you, and product design. According to the expensive cost of changing molds, product design should be very considered.

How to Choose A Reliable Injection Mold Maker

If you want to enter mass-production market, you should by a injection mold machine. There is another problem, which is how to choose a reliable injection mold maker.

A complete production sale process include pre-sale and after-sale. The experience for a injection mold maker is very important. The machine maker you seek for should be proficient to deal with any potential problems that machine may have. Thoughtful after-service is another considering factor you should think when you choose injection mold maker. Delivery, maintain, install machine on you production line. A reliable injection mold maker should have comprehensive service for their customers.

If you want to know more about mould for plastic injection, please comment and spend e-mails to us!