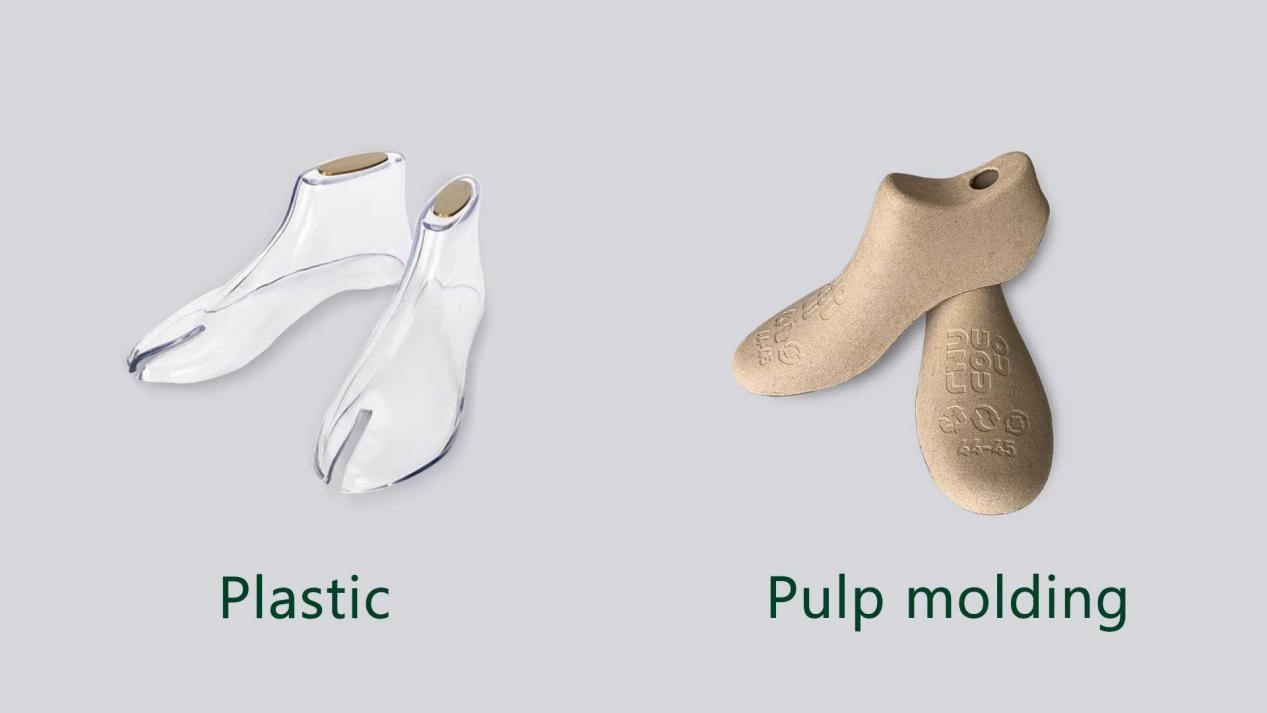

From non-biodegradable to biodegradable material, from biodegradable to fully compostable material, molded pulp plays an eco-friendly role in sustainable packaging and becomes a new favorite in the packaging industry. It is becoming more and more critical for us to know why the molded pulp packaging can replace plastic and deeply understand its advantages and disadvantages.

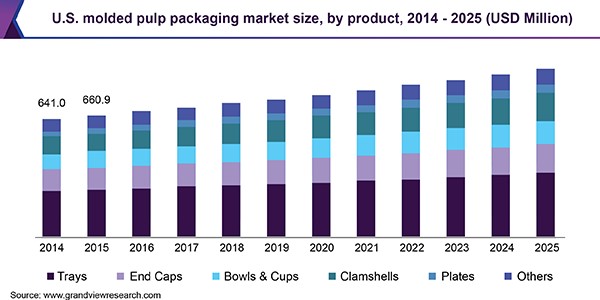

Pulp molding technologies are changing the packaging industry. Global Market Insights Inc. reports that the molded pulp packaging industry is projected to reach a value of $4.3 billion by 2026[1]. Compared to plastic packaging, the molded pulp packaging industry’s growth is expected to grow exponentially in the coming years. The average growth rate of the molded pulp packaging industry is 4.9% [2], and this is the percentage that this packaging solution is expected to replace plastic every year.

The data shows a trend in that plastic packaging is replaced by molded pulp packaging. And the reasons behind it are more apparent with the appearance of advantages of pulp molding packaging and the disadvantages of plastic packaging.

Reasons that molded pulp packaging can replace plastic packaging.

- Consumer-Driven

The public’s awareness of plastic waste in the environment has been at its highest ever. The Google trends of Interest over Time index shows compared with 2016, the rate of social interest in plastic waste and pollution quadrupled in 2019. And some findings in the 2018 Paper Packaging Consumption Trend Report also confirm that 64% of Americans thank they prefer paper rather than plastic or polystyrene foam packaging in electronic products, food, and general industries. And 48% of them tried to reduce the use of plastic items such as straws, plastic cups, bags, and shoe trees.

65% of people said that compared with five years ago, the sustainability of paper packaging is more relevant. Mintel, a staff of Consumer Research Company, predicts that sustainability is one of the five major trends that will affect the packaging industry in the coming year, which brands will be appealed to put marine protection at the forefront in packaging development.”

- An increase in plastic packaging bans globally

Italy was the first country in Europe that tried to ban plastics nationwide after legalizing a plastic bag ban on December 22, 2010, and implementing it on January 1, 2011. Germany, Britain, France, China, South Korea, Etc. Successfully passed the ban on plastics.

Nowadays, there has been a significant increase in the prohibition of plastic packaging across the globe because plastic is not biodegradable and will linger for over 450 years, destroying ecosystems. While molded pulp packaging is biodegradable, which means it can be composted. The compostability of molded pulp packaging is healthy for both the soil and the environment.

It comes as good news to the players of the pulp packaging industry. The ban on plastic will encourage more businesses that carry out pulp molding machines to use sustainable and eco-friendly packaging solutions.

- Expansion of the employ of pulp molding

At the stage of beginning, molded pulp packaging was widely employed in livestock and agriculture due to its natural characteristic of shock absorption. In agriculture, molded pulp’s shape and size should be similar to certain fruits to protect against scratches and mildew during long-distance transportation.

With the technical upgrading of pulp molding and the demand for packaging of products, the application range of pulp molded packaging has gradually expanded from egg carton to various industries, including food, electronic, medical, and health-care product, and other industry Etc.

Molded pulp has excellent characteristics of compression resistance, shock absorption, and sufficient heat resistance. It has a variety of protection functions, including blocking, supporting, and buffering. Because of these characteristics, electronics manufacturers are widely using the molded pulp in their products. Besides, it is expected that in the next few years, the development of the global electronics industry will strengthen the molded fiber pulp packaging market.

- The cost-effective green circular production system

Compared with traditional plastic packaging, on the one hand, plastic packaging’s production process produces harmful chemicals. On the other hand, plastic packaging will bring environmental problems. Due to its biodegradability characteristic, it can be existed on the ground for centuries, releasing harmful chemicals into the soil. However, the production of molded pulp packaging using the pulp molding machine poses no harm to the environment. And the production line from the selection of raw materials to the final product is a green closed-loop without harmful gases and substances.

Molded pulp packaging can do everything plastic packaging can and even better as it is cost-effective and has tons of environmental benefits instead of plastic, which leads the trend to replace the plastic packaging with mold pulp packaging.

Seeing the increase in demand for pulp packaging, packaging companies may have to restructure and become pulp molding machine manufacturers. HGHY is among the pulp molding machinery manufacturers that help many companies quickly and successfully transform into sustainable packaging field. That is thanks to their line of superior pulp molding machines used to produce a myriad of industrial packaging products. HGHY pulp molding machines come in all customize platen sizes, drying tunnels, and are also effortless to use and maintain. The machines are versatile, durable, and ideal for all molded pulp packaging needs of furniture, home appliance, electronics, auto parts, Etc.

Reference:

- Molded Pulp Packaging Market is likely to surpass $4.3 billion by 2026, Says Global Market Insights Inc. | globenewswire.com. (May 04, 2020). Available at: https://www.globenewswire.com/news-release/2020/05/04/2027161/0/en/Molded-Pulp-Packaging-Market-is-likely-to-surpass-4-3-billion-by-2026-Says-Global-Market-Insights-Inc.html (Accessed: August 24, 2020)

- Molded pulp packaging market | grandviewresearch.com. (12, 2019). Available at: https://www.grandviewresearch.com/industry-analysis/molded-pulp-packaging-market (Accessed: August 24, 2020)