Wood is a natural, environmentally friendly material. Therefore, wood products are so in demand to create coziness and a special atmosphere in the house. Wood is used for furniture, doors, stairs, wall panels, and home decor. Even small carved details will give luxurious look to all wooden furniture.

Carved furniture has been valued for centuries and is classic, reference furniture. Wood milling allows shaping the workpiece into the desired shape using a rotary cutter, drill, or cutter. The milling method turns an ordinary piece of wood into a work of art.

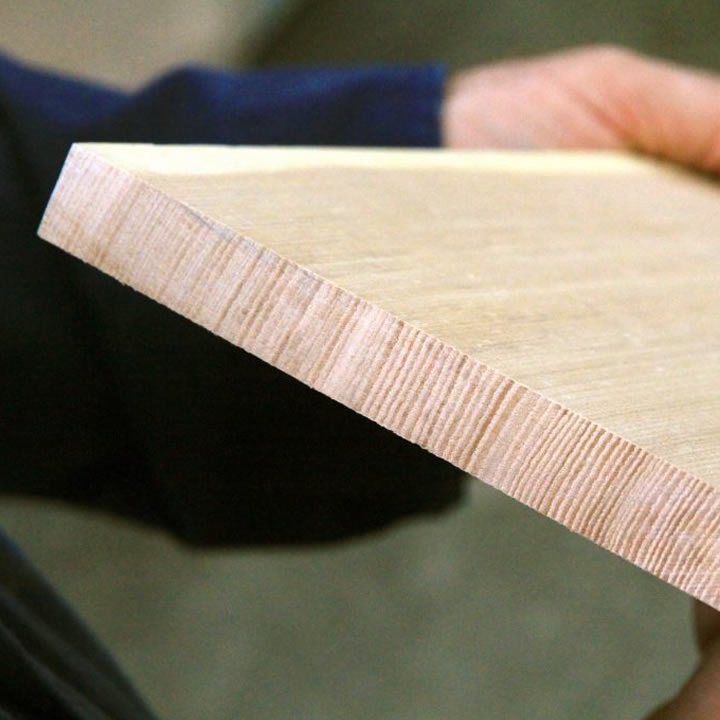

Each type of wood has its own unique properties and texture. Maple and ash-tree are the most popular for custom milling jobs. Oak, beech, birch bark are less popular but also are used in furniture production.

In the modern world, in the era of full automation and robots, when the main criteria for any product and service are price, quality, and production time, CNC milling machines perfectly cope with the tasks, taking on all the functions of manual woodcarvers, and making significant progress ahead in speed and quality of wood milling.

Industrial Knives & Blades

Industrial knives are an indispensable part of production equipment. They are responsible for the quality of woodworking equipment, crushing units, metal cutting machines, and so on.

That is, we can conclude that the woodworking, metallurgical, and even pulp and paper industries carry out work with the help of such devices.

This is not all the purpose of industrial knives, in addition, they are used in the processing of plastics, printing, agriculture, and even in the food industry. Industrial-type knives are used very widely and in different equipment, respectively, they can have different shapes and sizes.

Such knives are made from high-quality materials, mainly the raw material for the manufacture of such knives is a strong steel that can withstand extremely high loads. Despite the fact that industrial knives differ significantly in many respects, they are classified according to their purpose.

Types of industrial knives

- Guillotine knives are used in the metallurgical field. With the help of such knives, more precisely, with the help of the equipment in which they are installed, metal is cut.

- Chipping knives are used in the woodworking and pulp and paper industries. With the help of such knives, technological chips are made, that is, chipping knives are elements of chipping machines.

- Shaving knives are intended for the manufacture of wood chips, in addition, with their help, wood is cut.

- Circular knives – can be used on equipment for various purposes, but it should be noted that circular knives can have different diameters. Knives with a diameter of 400 to 600 millimeters are considered standard, but if a person needs knives of a different diameter, then they can be made to order.

BKS Knives is an industrial knife manufacturer that offers a wide range of customized industrial blades. The company creates industrial blades made to measure, such as rotary cutters, industrial circular knives, industrial straight knives, toothed blades, and much more.

BKS offers both the creation of new blades and the sharpening of blades on various turning, milling, welding, and of course cutting rotor of grinding machines.

The company is an expert in the production of industrial-grade blades and knives. The products made by BKS are designed in Europe and Asia with one constant: OEM quality. As a leading industrial knife manufacturer, BKS produces high-quality and professional knives and blades.