CNC stands for computer numerical control. In this case, CNC machines can control another machine through a set of commands coming from its control. Before delving deeper into CNC Swiss machines, perhaps it is better to have a good idea first on what Swiss screw machines are and how they work.

How Swiss Screw Machines Work

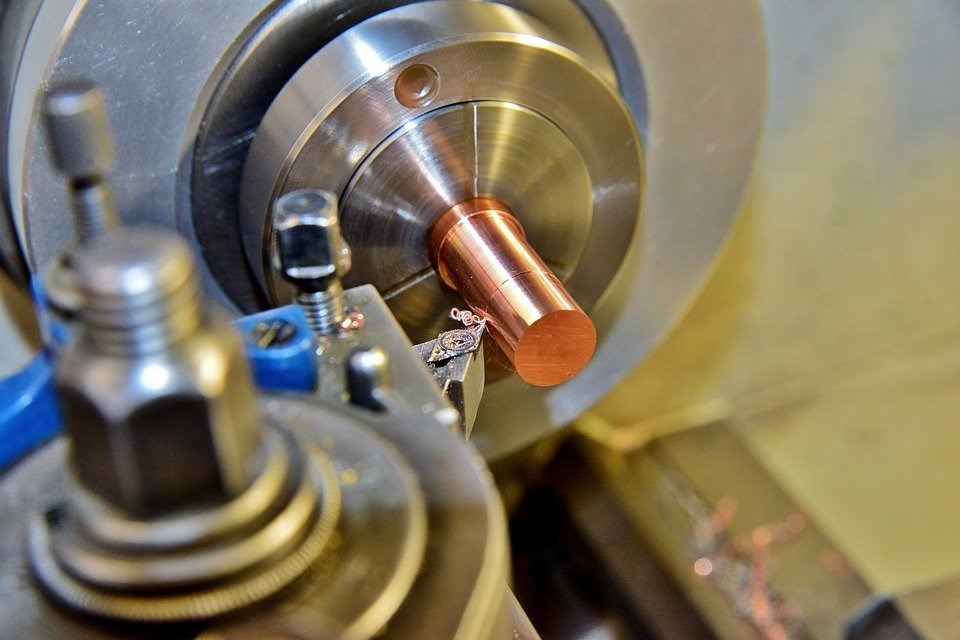

The term screw is somehow misleading because a Swiss screw machine doesn’t screw any parts in or thread materials through, even if this is one of their numerable functions. Rather, these machines shave metals down to the desired size by spinning on a rapidly rotating lathe. More often than not, the Swiss-type is used for precision components, mounting the work-piece on a rotary slide. Aside from the Swiss-type, another type of screw machine is the Turret type. With this machine, the work-piece is mounted on a vertical ram that works into the lathe. Even if the two types of screw machines may function differently, the output they generate is very much similar. These also prove to be more efficient than manual works.

Types of Swiss Screw Machines

Focusing more on the Swiss screw machine which is better at more precise work compared to the Turret type, it is time to delve into its two common types.

● Automatic Screw Machines

Automatic screw machines function with a disc cam that moves the tools in a radial motion. A collet holds the work-piece in place while the disc cam rotates the tools into it. The manner that these machines work is very much similar to a spindle collet that prevents the issues brought about by the deflected debris.

● CNC Swiss Screw Machines

CNC turning machines or lathes operate on the same principle as the automatic screw machine, only that its operation is controlled by a CNC unit. Because of this, CNC Swiss machining features more sets of tooling. As a result, more operations on the same piece is performed in a shorter period. Because of its precision, this machine is prevalent in the automotive, information technology, as well as in the consumer electronics industry.

➢ Types of CNC Swiss Screw Machines

The CNC Swiss screw machines can be categorized further into four types namely the lathe, mill, drill, and grinders. A CNC lathe can create curved surfaces that a manual lathe may not be able to produce. A CNC mill is used to generate flat parts. A CNC drill is somehow similar to the CNC mill, but these are specifically designed to only cut along one axis. A CNC grinder creates high-quality surface finishes by grinding the wheel into the material. More often than not, these grinders are used during the finishing processes.

To wrap things up, it can be deemed that the use of CNC machines has several benefits. For one, its process is faster than manual machining and because of this, production costs are reduced. These machines also have higher efficiency and increased safety. Because of these reasons, it will come as no surprise if these machines are already prevalent in several industries.