3D Printing has undoubtedly experienced one of the fastest rises among modern technological trends. The concept, which has won the appeal of enthusiasts from all walks of life, is rapidly becoming an integral part of core professions like engineering, R&D, DIY, product development, etc.

Since 3D printers are now so widespread and becoming easily accessible to the layman, questions and confusions about the tech are common. As a company that specializes in 3D Printers and values its customer base, it is imperative for Flashforge to share with you helpful information that will make your 3D printing journey smooth and enjoyable.

The following discussion takes you through the various nuances among black PLA, ABS, PETG, and more. Hope you get clear about which filament is best for your 3D printer after reading this article.

3D Printing: A Technological Revolution

Additive Manufacturing is still a new field and there is a lot of research around the globe centered on it. Owing to its unique manufacturing method and massive interest by academia, it has become a highly technologically diverse field. There are multiple kinds of 3D printers, each employing its own technique and material, which are readily available in the market.

As a result, before deciding which filament is better, it is imperative to know what exactly is a ‘filament 3D printer’ and how is it different from others.

Generally, technologies are categorized with respect to the form of raw material they use. It can be a filament, liquid resin, powder, etc. While there are many types to discuss, the two broad divisions in 3D printers are filament-based and resin-based.

Resin-Based 3D Printers

In the context of 3D printing, resins are viscous, liquid compounds derived from natural sources or synthesized, that are capable of being turned into solid polymers. The chemical reaction that enables this transformation is initiated by exposure to some form of light, typically Ultraviolet Radiation (UV Light).

Resin-based 3D printers use such principle to fabricate solid prints out of liquid resins. Using the slicing software to slice the digital 3D model into many layers and transmit the sliced model to the 3D printer. UV light from the resin 3D printer would selectively irradiate on the resin layer by layer, which leads resin to solidification layer by layer and finally forms a whole object.

There are several types of resin-based 3D printers, the common ones being SLA, DLP, LCD/MLCD, etc. All do the exact same thing described above but in a different way.

Figure 1: Flashforge Foto 8.9 LCD 3D Printer

If you are looking for a decent resin 3D printer for your DIY projects, the Flashforge Foto 8.9 is an impressive LCD Resin 3D Printer that is designed to meet all your requirements.

Filament-Based 3D Printers

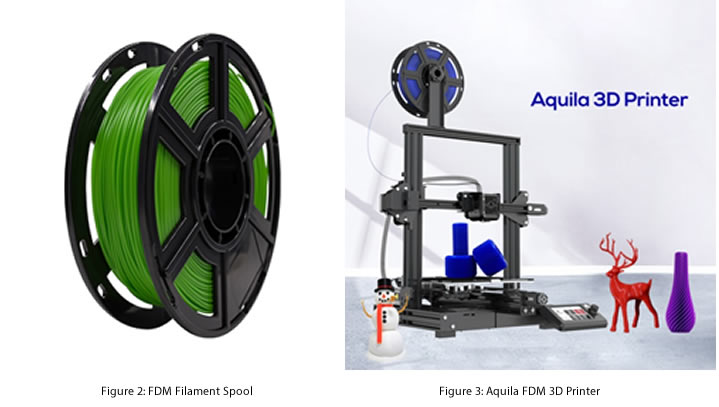

These printers follow a simple principle. They take raw material in filament form, heat and melt it up in a device known as the hot end, extrude it onto a bed through a nozzle, and make the extruder step in a specified path to constructing layers by layers. The filament, to be clearer, is like a thick thread and comes wrapped on a spool, just like a reel of thread. You can seek and compare high-quality filaments on Flashforge online shop.

Fused Deposition Modelling (FDM), also known as Fused Filament Fabrication (FFF), is the core technology of a filament 3D printer. FDM Printers are by far the most popular among users, hobbyists, and professionals alike. Flashforge sports a top-of-the-line fleet of FDM 3D Printers that you can browse Flashforge online shop.

In general, the most commonly used printers by normal makers and individual customers are Resin and Filament printers. About resin knowledge and which resin to choose if you have a resin 3D printer, I will write it in a new article. Here in the following part gives a detailed description of filament types and which is proper for your FDM 3D printers.

Which is the Best Filament?

When it comes to filaments, there is a huge, almost non-documentable variety. Filaments come in different materials, some are fiber or powder-infused, with different mechanical and aesthetic qualities, and their own propensities towards different kinds of failures.

The answer to the big question simply is, no filament is perfect! Each one has its own pros and cons and it is really that your specific application decides which one is ideal for you.

PLA, Polylactic Acid

The Mighty PLA! The favorite and most popular filament out there. PLA is compatible with every FDM printer brand and is the preferred filament by many customers. The major pros of PLA include its good thermal performance, low warping, and variety in colors. Black PLA is quite popular among users though.

PLA melts and solidifies relatively quickly at temperatures of 190-220℃, which means that users do not need to purchase heavy-duty extruding assemblies to tackle high temperatures. It becomes solid as soon as it is extruded, offering a great advantage in terms of rigidity during printing, allowing for overhang and bridge features, hence lesser need for supporting scaffolds. However, overheated bed during printing may cause jams inside the nozzle due to the consequent softening of PLA.

Moreover, PLA is among the cheaper filaments and, most importantly, it is harmless to use, both for humans and the environment. It is a renewable product that can be recycled!

Mechanically, it is not that strong, and along with the thermal softening mentioned above, it is not ideal for functional products. It is, however, a great fit for rapid prototyping purposes and decorative items. Hence, if you are a starter or a fan of aesthetically pleasing print, PLA is the way to go.

ABS, Acrylonitrile Butadiene Styrene

ABS is the top choice of many, owing to its spectacular mechanical properties. The material is not exceptionally different from PLA but there are some nuances.

To start with, it is tougher and harder. As a result, ABS parts are strong and resistant to deformation, hence requiring an extruder bearing higher temperature (220-240°C). The surface finish can be drastically improved to become almost glossy through the use of Acetone, which reacts with it to dissolve it. Diversity in color is also an advantage of ABS. Not only is there black PLA filaments, also there are black ABS and other colors.

A few to mention here. First of all, ABS has a tendency to warp very easily. During printing, it is prone to changing dimensions as it cools down, leading to low dimensional accuracy and errors like elephant’s foot. To tackle this, users need a heated base + adhesive and well-controlled hot end, which increases the cost.

Additionally, unlike PLA, ABS produces pungent fumes during printing. Users need protection against this, which necessitates a ventilation system as well as a printer enclosure.

Overall, ABS enjoys superior mechanical properties and is widely used for functional purposes. A number of supporting parts, consumer products like toys, showpieces are 3D printed in ABS.

PETG

PETG is like a hybrid between PLA and ABS. It boasts the mechanical toughness possessed by ABS while having a good thermal performance like PLA.

It can take a good impact, has a desirable brittleness/ductility balance, and is extruded well if the temperature gradient is well-maintained. Having said that, it is pertinent to add here that warping is an issue in PETG that needs to be controlled via a heated bed. If not, it can sag considerably and decrease important features like overhangs.

PETG lies on the cheaper price range among filaments and has remarkable post-processing provision as well. You can weld and sand it to a considerably smooth finish, and even machine it due to its elite toughness.

Anyhow, this unique combination of properties makes PETG a good candidate for people who are printing working models and are also a fan of good looks.

TPE, Thermoplastic Elastomer

TPEs are an incredibly interesting type of 3D printer filament. It is fun to use them but….. mind it, after printing. Despite their rare qualities, they are difficult to manage during the printing process.

This brand of filament is also known as flexible filament. They are flexible in the regard that they are soft and rubbery, they can be stretched and twisted, all without breaking. The characteristic rigidity of PLA, ABS, and PETG is not present here.

The problem: when they melt they stick to the inside of the extruder/nozzle walls. Overheating causes them to completely melt out and lose the necessary strength to bear their own weight. Low temperature, on the other hand, leads to clogging and sticking, which has the potential to ruin the entire print. Thus, you have to be extra careful with the temperature settings and bed heating.

In conclusion, TPE is certainly the best-suited filament if your target property is shock-absorbance and damping. Protective covers and springy elements are common applications. You have to, however, avoid extreme temperature environments.

Composite PLA

Composite PLA filaments receive an honorary mention in this blog owing to their versatility and innumerable applications. This is not one kind of filament; composite PLA filaments can be any combination of materials mixed together with normal PLA.

The infused agent can be carbon fibers, metallic powders, glow-in-the-dark elements, glitter….. You name it!

Each composite has its own qualities, which is a combination of the properties of PLA and the other agent. For example, Carbon-Fiber-Infused PLA is extremely stiff and has a finish like carbon fiber components. The extruded material is also comparatively rigid during extrusion, helping it settle better.

Similarly, glitter is often added in PLA for cosmetic purposes, beautifying the product with dazzling colors and shine.

Composite PLA, however, as discussed below, still is not perfect. If you do not need them in your application, they are certainly not ideal for you if you don’t need to produce an object with such property.

Conclusion

Among PLA, ABS, PETG, TPU, PLA is mostly recommended for normal makers. You can see via Amazon that the top-seller of filament is black PLA and PLA pro. Hot-selling brands are Flashforge black PLA filament and hatch box black PLA. Sincerely hope this article was helpful for our readers on their 3D printing projects.

Flashforge is a company dedicated to delivering quality 3D printer products and services to its clientele, offering an outclass range of 3D printers that will perfectly complement your passion, business, or institute. Take a look at our Dreamer product series on Flashforgeshop if you plan to teach 3D printing in an educational environment or look at the captivating Creator 3, which is a dual extruder FDM 3D printer with industrial applications.