The history of the appearance of heat exchangers

Heat exchangers have existed since the appearance of man on earth and even before it. The sun during the day heats the sea, rocks, and earth, at night the natural heat exchanger gives off heat, maintaining the balance of heat on the earth.

The red-hot core of the earth also warms our planet’s surface.

It is a historical fact that references, for example, to a plate heat exchanger can be found on frescoes dating back to the 6th century BC. The principle of heat transfer from one medium to another is described in the therms – ancient Greek baths.

Ancient warriors also used their armor to get hot water by putting hot coals in them and lowering the armor into a barrel of water. But these are all historical concepts – what is a heat exchanger.

What are heat exchangers?

A heat exchanger is a device whose main function is to transfer thermal energy from one working medium to another. A gaseous substance, acids and alkalis, steam, water, and various solutions can act as a heat carrier.

Lamellar (made from small rectangular plates) units are recognized as the most popular heat exchangers today. They are successfully used in the following areas:

- chemical industry

- oil refining industry

- gas industry

- atomic industry

- petrochemical industry

- energy industry

- communal areas

The design of the device, the material of components, and other parameters must be selected based on the characteristics of the technological process and the required performance.

The following areas of use of heat exchange equipment are distinguished:

- cooling systems

- heating systems

- air conditioning systems

- chemical industry

- pool heating

- solar collectors

- mechanical engineering

- ventilation systems

- metallurgy; pharmacy

- auto production

- food industry

In addition, it is possible to use heat exchange equipment for heating private households. The use of this technique helps to evenly distribute heat in the room.

What is a modern heat exchanger made of?

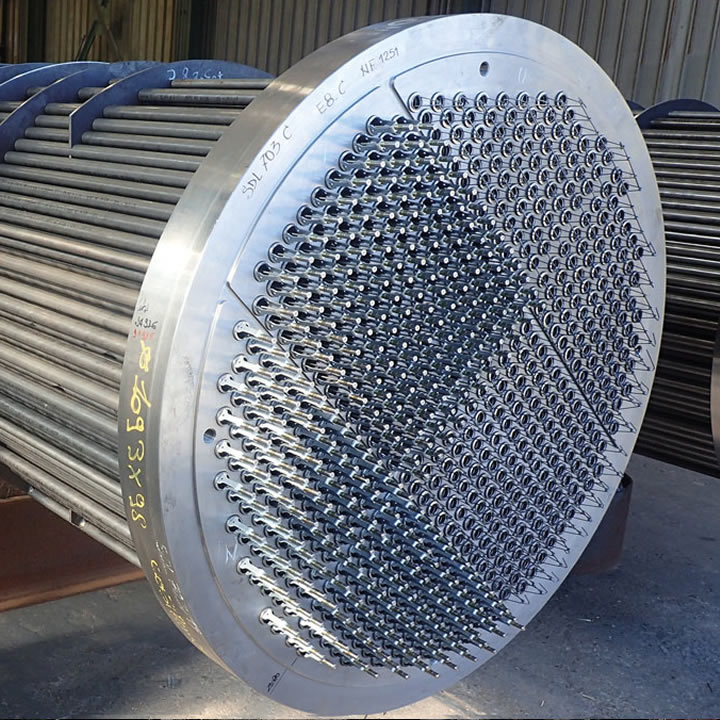

A modern type heat exchanger consists of several parts, each of which plays its own important role:

- fixed plate, to which all inlet pipes are connected

- pressure plate

- heat transfer plates with inserted gaskets of sealing type

- top and bottom guides

- rear rack

- threaded pins

Descaling of plate heat exchangers

Descaling is a necessary maintenance operation for plate heat exchangers if they are not equipped with antiscale devices. Cleaning of plate heat exchangers is divided into chemical, chemical collapsible, and mechanical collapsible.

Chemical cleaning consists of the fact that a cleaning agent is poured into the system based on some acid and the circulation of the reagent is organized by a special booster pump.

After several hours of circulation, the detergent is drained off and the system is flushed with an alkaline solution to neutralize the acid.

If the heat exchanger is contaminated to such an extent that it is impossible to organize normal circulation, the heat exchanger is dismantled, and wash each plate individually with brushes, sandblasting, or water jet under high pressure.

A brazed plate heat exchanger clogged with scale must be replaced.

You can read more about the heat exchangers’ cleaning process at HeatExchangerCleaner.com