The landscape of industrial manufacturing is undergoing a profound transformation, driven by advancements in technology, shifts in global economic patterns, and changing consumer expectations.

Once characterized by labor-intensive processes and efficiency at scale, the sector is now pivoting towards agility, customization, and sustainability. Let’s talk about the role of industrial manufacturing, the key drivers of change, and the impact these are having on the industry.

Embracing Digitalization and Smart Manufacturing

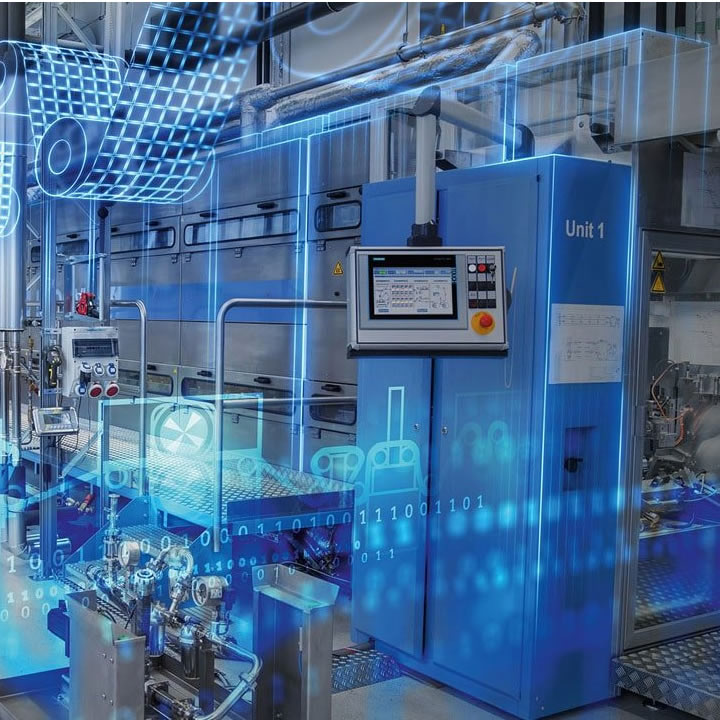

At the forefront of this transformation is the digitalization of manufacturing processes.

Integrating digital technologies—such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics—into manufacturing operations, commonly referred to as Industry 4.0, fundamentally alters how factories operate.

These technologies enable smart manufacturing, where machinery and equipment are interconnected and capable of making autonomous decisions. This shift not only enhances operational efficiency but also improves the accuracy and speed of production lines.

For example, IoT devices can monitor equipment performance and environmental conditions in real time, allowing for predictive repairs for parts like power supplies to minimize downtime.

Similarly, AI algorithms can optimize production schedules and supply chains dynamically, responding in real time to changes in demand or production capacity. These technological integrations make manufacturing processes more responsive and less wasteful, driving down costs while boosting productivity.

The Rise of Customization and On-Demand Manufacturing

The traditional mass-production model is being challenged by increasing consumer demand for customized products. Advances in digital technology have made it economically viable to produce smaller batches of customized items without significant cost increases.

Technologies such as 3D printing are at the heart of this shift, enabling manufacturers to produce complex and customized products as easily as standard ones. This trend is not only changing the production processes but also transforming inventory management and logistics, as the need for large inventories of finished goods is reduced.

Sustainability and Circular Economy

Environmental sustainability has become a critical consideration in industrial manufacturing. Driven by regulatory pressures and a growing awareness of environmental issues among consumers, manufacturers are adopting practices that minimize environmental impact.

This includes the use of renewable energy sources, recycling waste materials, and designing products with their entire lifecycle in mind.

Furthermore, the concept of a circular economy is gaining traction, emphasizing the need to reuse materials and products to the greatest extent possible. This approach encourages manufacturers to design products for durability, reuse, and recyclability, significantly altering the traditional manufacturing and consumption models.

Workforce Transformation and Skills Evolution

As the role of automation and AI continues to grow, the skills required in the manufacturing sector are evolving.

There is an increasing demand for workers who can manage complex systems and work alongside advanced machinery. This shift necessitates a significant investment in training and development to equip the workforce with the necessary skills.

Moreover, the role of human workers is changing from repetitive manual tasks to more strategic, analytical, and technical roles. This not only helps in managing the sophisticated machinery and systems of modern manufacturing but also in driving continuous improvement and innovation within the sector.

Global Supply Chain Reconfiguration

The globalization of supply chains is being reevaluated in the face of rising geopolitical tensions, trade wars, and disruptions such as the COVID-19 pandemic.

Manufacturers are increasingly looking at reshoring or nearshoring production facilities to reduce dependency on distant markets and mitigate risks associated with global supply chains. This trend is accompanied by an increase in the use of automation and robotics, making it cost-effective to manufacture goods closer to their markets.

Collaboration and Co-Creation

The complexity of modern manufacturing products, particularly those embedded with electronics and connectivity, is fostering greater collaboration across different sectors and disciplines.

Companies are increasingly engaging in partnerships and collaborative projects with tech firms, researchers, and start-ups to innovate more effectively. This co-creation approach leverages external expertise and resources, speeding up the innovation process and bringing more sophisticated products to market more quickly.

Conclusion

The role of industrial manufacturing and automation is changing dramatically, influenced by technological, economic, and social shifts.

As the sector continues to embrace digitalization, customize its offerings, integrate sustainability, adapt its workforce, reconfigure supply chains, and foster collaboration, it is setting the stage for a more agile, efficient, and responsive manufacturing landscape.

This transformative shift not only ensures the survival of manufacturers in a competitive global market but also enhances their capacity to meet the future needs of society and the economy.

The evolving role of industrial manufacturing is not just about adopting new technologies but about rethinking the entire production and business models to stay relevant and thrive in the years to come.