The presence of foreign matter in the infusion or vaccine bottle is a potentially dangerous scenario that leaves patients in horror, feeling like they can’t trust the medical companies.

Foreign matter points to contamination, which can occur due to faulty inspection. For many years the gold standard was manual inspection, but is it time to start increasing the use of automated inspection machines instead?

What about the foreign matter in the bottle? Recently, patients and the world were left shocked as the news emerged about contaminated vaccine bottles in Japan.

A pharmacist noticed foreign, black matter in vaccine vials which prompted Japan officials to put the entire batch on hold due to contamination. The problems like this one occur due to one factor primarily – faulty inspection.

The main purpose of the inspection is to ensure safety and prevent contamination. Inadequate inspection leads to “invasion” of foreign matters that may jeopardize patient safety.

Two types of inspections

Inspection is crucial in the pharmaceutical and medical industry. It can be performed in two ways: manual and automated.

- Manual inspection: The term manual inspection refers to the process where human operators follow the SOP (standard operating procedure) to inspect ampoules, vials, and bottles visually. Human operators sometimes use a microscope for inspection purposes, but they largely rely on the naked eye.

- Automated inspection: An automated inspection is a process where the inspection machine does all the work. The machine relies on operating systems and a wide range of features to detect irregularities such as impurities, cracks, liquid levels, among other things.

The human operator does not inspect the ampoules or vials, so there is no need to use a microscope or naked eye.

Pros & con of these two inspection methods

The manual and automated inspection methods differ in many aspects. Below, you can see how they compare to one another and which method outperforms its counterpart.

Quality (Knapp-Test)

Knapp-test, a particle test set, is carried out to ensure the manual inspection is comparable or similar to the automated inspection. The process is generally time-consuming.

Undetected rate: With an automated inspection machine, no error escapes undetected. The reason for that is simple; these machines feature camera detection with outstanding image acquisition and processing. At the same time, they have fast operating systems that easily detect all the irregularities.

The machine has sorting systems that immediately arrange the analyzed items. On the other hand, manual inspection is different, and even the best human operator is unable to detect absolutely every abnormality on the vial, ampoule, bottle, or cap.

Erroneous rate: The high accuracy of the automated inspection machine minimizes the risk of errors. That ensures the quality of the content and cuts down the likelihood of contamination.

However, manual inspection is only about 80% to 85% effective. While this isn’t bad, it still means the remaining 20% accounts for inspection errors.

Although 20% may not seem like such a big number, it’s staggering if we bear in mind patients’ safety is at stake. It’s not humanely possible to manually inspect everything with a naked eye or microscope and not make a single error.

Economic efficiency

Automated inspection machines and manual inspection also have a lot of differences in terms of economic efficiency. Below, you can see how they compare.

Speed: When it comes to speed, an automated inspection machine is a clear winner here. You see, this inspection equipment can inspect or analyze hundreds of vials, ampoules, or bottles per minute. Manual inspection can’t match that. Relying on a microscope or naked eye is time-consuming. So, a human operator can’t thoroughly evaluate hundreds of items in 60 seconds.

Capacity: Capacity is closely related to speed—the faster the inspection, the bigger the capacity, i.e., the number of items processed. Since the automated inspection machine is faster, it handles hundreds of items. On the other hand, slow manual inspection has a lower capacity.

Cost: Automated inspection machines come at different costs, depending on their quality, the manufacturer, and other factors. Manual inspection has some costs, such as those including management and overhead.

However, it may not be a more affordable option in the long run. How? While automated product inspection systems are more expensive to buy, they can help a company save more money with time. The reason is simple; these machines increase productivity, inspect more items, and it translates to more income.

So, which method wins?

When you compare automated inspection machines and manual inspection, it’s easy to conclude the latter can’t compare to automatic units. Inspection machines are highly popular thanks to their high accuracy and efficiency. They’re a clear winner here.

While automated inspection should be an integral component of your production process, it doesn’t aim to replace manual inspection entirely. Instead, an automated inspection can be supplemented by manual inspection to get the best of both worlds.

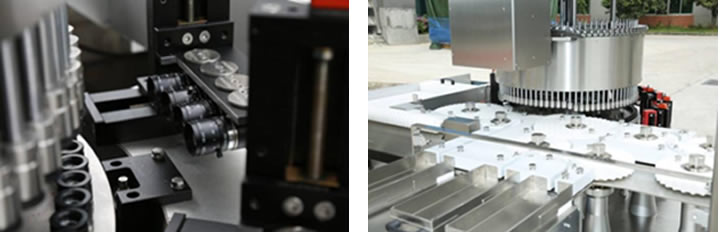

Pharmapack’s PIM-72

Pharmapack’s PIM-72 is an automated inspection machine that can take productivity in medical or pharmaceutical products as well as patient safety to a new level. The main advantages of this machine include:

- High speed (max speed 800 vials/min, steady speed 600 vials/min)

- High precision and accuracy

- Camera detection (image acquisition and processing)

- Micro-computer control and touch screen

- Made from stainless steel and aluminium

- Easy to use

- Performs different inspections

- Sorts items automatically

Conclusion

Inspection is vital in medical and pharmaceutical industries to prevent contamination of products and medications formulated for patients. Of the two types of inspection, the automated inspection method is more effective. The machines are faster and more accurate than the naked eye or microscopes.

For that reason, if you want to ensure the quality of the content in ampoules, bottles, or vials, you should definitely invest in a high-quality automated inspection machine, like Pharmapack’s PIM-72.

As one of the most reliable manufacturers of automated inspection machines, Pharmapack puts a strong emphasis on continuous research that will provide the best solutions.